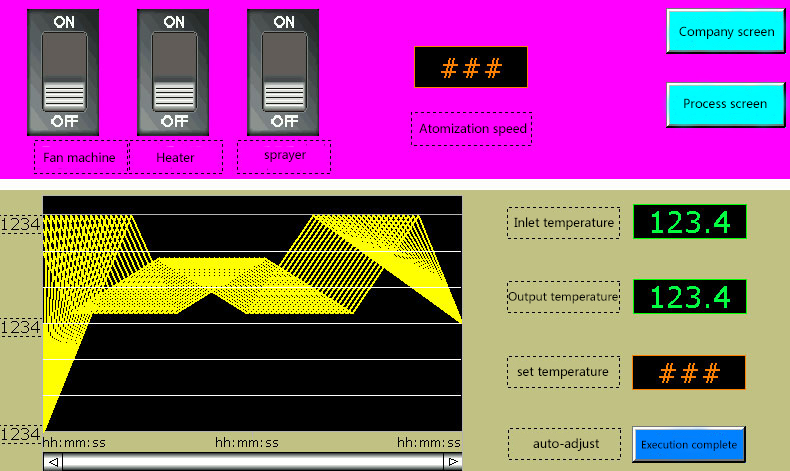

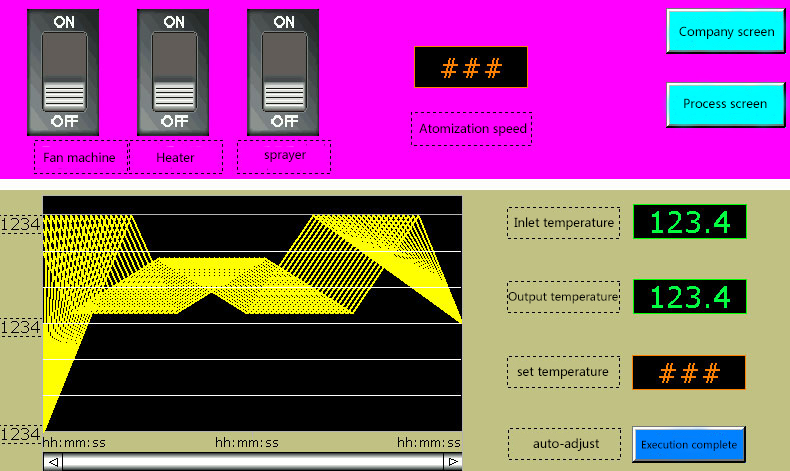

SP-5000 Spray Dryer Machine

Principle:

SP series spray dryer is improved many times, it is mainly suitable for the lower thermal temperature point, the viscosity of the liquid material drying equipment. The working principle is: cold air through the filter, and then into the heater, heated to a certain temperature, and then into the spray tower at the top of the air distributor, hot air was evenly to the bottom of the spiral run. The material is pumped to the top of the tower by the centrifugal atomizer, the material is torn into a very small mist droplets, liquid droplets and hot air and flow contact, while full heat exchange, liquid Containing water quickly vaporized, evaporated, dried in a very short period of time for the finished product, finished by the cyclone separator after the discharge emptying, waste steam discharged by the induced draft fan.

Feature:

1. The equipment drying time is short, only need 5 seconds, the general effective ingredients will not be destroyed.

2. Spray tower diameter can adapt to a variety of materials to dry, inlet and outlet air temperature is adjustable air temperature, wide range of work.

3. Equipment configuration is complete, to meet the production process requirements from the maximum extent.

4. Simple operation, wide range of adaptation, no professional operators.

5. Unique inlet screw distributor, is the company's patent, to ensure that the tower in the circumference, the air flow is absolutely uniform down, to minimize the material sticky wall.

6. Advanced and convenient cleaning door, can facilitate the operation of workers, but also to ensure absolute sealing, so that the material is not sticky wall, the tower is equipped with a clean door, to facilitate all-round cleaning.

7. tower absolute mirror polishing, without any dead ends, one is to avoid sticky material, the second is to facilitate cleaning.

8. The inlet temperature is controllable and can fully satisfy the drying process of the material.

9. All pipes, cyclones are equipped with quick opening mouth.

10. Heater is improved into a U-tube form, to overcome the heating tube thermal expansion and contraction caused by weld cracks. U-shaped tube outside the shell, to avoid the air leakage between the pipe and the tube. Fins with aluminum alloy, improve the heat transfer coefficient and heat transfer efficiency.

Specification:

1. Water evaporation:5Kg/h

2.Heating power:18kw

3. Inlet air temperature:160~250℃(depends on the material)

4. Outlet air temperature:80~90℃(depends on the material)

5.Heating temperature accuracy:±1℃

6.Weight:300KG

7.Size:1800×1500×2500 ( mm ) L x W x H